This is a simple way to create purchase orders for both stocked and non-stocked parts.

Parts must have a primary supplier to be included in the auto-build regardless of whether the part is stock or non-stock in Inventory or whether it is a non-stocked part not listed in Inventory.

To Build Purchase Orders from Stocking Levels

To build a replenishment purchase order, complete these steps:

- Click the P.O. Mgmt button in the toolbar

.

. - Click the Auto Build button from the Purchase Order Management toolbar.

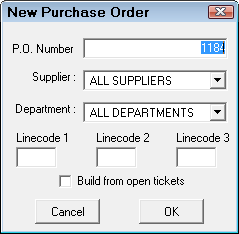

- You are prompted to select the

- P.O. Number - The number of the first purchase order if more than one purchase order is generated

- Supplier or All Suppliers (This can take a long time and a purchase order is created for each supplier.)

- Parts department or All Departments

- You can enter one to three line codes if you wish to only order parts with those line codes

- Do not select the option to Build from Open Tickets.

- Click OK.

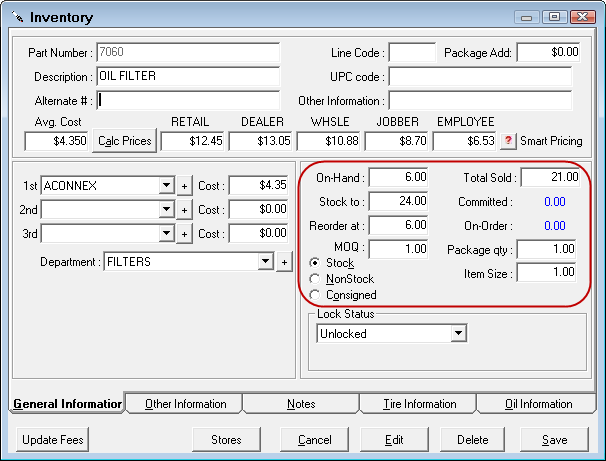

- This system searches for and finds stock parts that 1) match the selected criteria and 2) need to be ordered based on values in the Stock Information Section of the part in Inventory.

How R.O. Writer Identifies Stock Parts to Include in the Auto Build

Parts are identified by the On-Hand quantity being equal to or less than the Reorder At quantity. The Committed quantity (parts on open tickets) and the quantity On-Order (parts on purchase orders not yet posted) are taken into account as well.

The quantity ordered is the amount necessary to equal to the Stock To quantity.

In the example above,

- On-Hand (6) - Committed(0) + On-Order(0) = 6, which is the Reorder At quantity. Therefore, the part is included in the purchase order(s) created by the Auto Build.

- The quantity ordered is Stock To(24) - On-Hand(6) = 18.

NOTE: It is important to remember that the Committed quantity is subtracted from the On-Hand quantity automatically. In the example above, if there were four(4) Committed, then the On-Hand value would be two(2) not six(6).

After the purchase order(s) is created, the On-Order quantity is updated. On-Hand quantity is updated when the part is received and the purchase order posted.

For more information, see Stock Information Section.

To Build Purchase Orders from Open Repair Orders

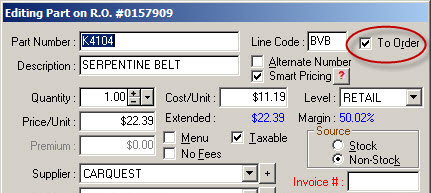

This process builds a purchase order for all the parts on active repair orders that

- Have the To Order box checked AND a

- Supplier selected.

You can build a purchase order for stock and non-stock inventory parts, as well as parts not listed in inventory.

Complete these steps:

- Click the P.O. Mgmt button in the toolbar.

- Click the Auto Build button from the Purchase Order Management toolbar.

- You are prompted to select

- The number of the purchase order (the beginning number if more than one purchase order is generated),

- The supplier (or all suppliers), and the

- Parts department (or all departments).

- Check the Build from Open Tickets option.

- Click OK.

- The open repair orders are examined.

- Any To Order part that meets the criteria is placed on a purchase order.

- The quantity ordered is the total quantity that is required on the repair orders.

After the purchase order is built, the On Order quantity is updated on parts that have local records in Inventory.